Product Description

General Information of Plastic Molding Part :

| 1 | Mould base material | LKM, HASCO, LOCAL ,DME, etc |

| 2 | Mould core material | 718H, S136H, NAK80 , P20, etc |

| 3 | Plastic molded parts material | ABS, ABS+PC, PC, PP, PVC, |

| 4 | Cavity | Single, Multi |

| 5 | Runner | Hot & Cold Runner |

| 6 | Finish | Semi-Matt, Polish |

| 7 | Design software | Pro-E, IGES, UG, CAD CAXA, ect |

| 8 | Main processing equipment | CNC, Cutting, Carved, Milling, EDM |

| 9 | Arrangement type | I-section, Straight body mould |

| 10 | Second Processing | Silk-scree Printing, Plating, Painting |

| 11 | Package | Wooden case for mould, carton box for Plastic Molding Part |

| 12 | Delivery time |

30-40 days for mould and samples of Plastic Molding Part, 7days for mass production. |

| 13 | Trade Term |

Ex-works, FOB Shenzhen, CIF |

| 14 | Payment Term |

Payment by T/T |

Follow us to visit our facotry:Cooperation with direct manufacturer for cost saving and high quality.

1. Company Landscape

2. Workshop:

3. Machines

4.1 Incoming Inspections : Material Reception, Incoming Quality Check (IQC) Records , Production Quality Check (PQC) records, and Final Inspection (FI) records are availiable

4.2 Manufacturing Process

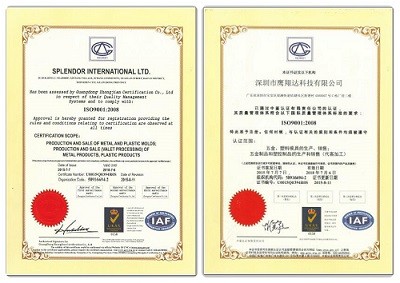

4.3 Quality Management: Certificated by ISO9001:2008

• There are 2 QC Managers to head the Quality Control function.

• Quality Manual for workers to keep high quality in mind

• There is a developed quality control plan showing inspection procedures used during manufacturing

Add: 2nd Floor, North of Indali Industrial Park, No. 96, Fuqian Road, Fumin Community, Fucheng Subdistrict Office, Longhua District, Shenzhen City, China 518110

E-mail: nicholas.lee@hksplendor.com sales@hksplendor.com splendor@hksplendor.com

Tel: +86-755-28019948 Fax: +86-755-28015009 Http//: www.hksplendor.com

Copyright@2013 Splendor International Ltd All Rights Reserved.